Advanced welding equipment revolutionizes automotive repair with unprecedented precision and efficiency. Computer-aided control systems, automated stabilization, and precise temperature regulation minimize errors, speed up processes, and ensure superior quality in metal fabrication and hail damage repair. This technology streamlines auto maintenance, contributing to safer, more efficient, and aesthetically pleasing end products.

Advanced welding equipment is transforming the industry, offering a game-changing approach to achieving clean and consistent welds. This technology isn’t just a trend; it’s a necessity for modern manufacturing. By embracing these innovations, businesses can unlock significant advantages, from improved product quality to enhanced safety and efficiency. Discover how advanced welding equipment revolutionizes traditional methods and becomes the cornerstone of any forward-thinking operation.

- Advanced Welding Equipment: A Game Changer

- Clean Welds: The Key Benefits Unveiled

- Consistent Results: How Tech Enhances Quality

Advanced Welding Equipment: A Game Changer

Advanced welding equipment has revolutionized the way we approach both industrial and automotive repair services, introducing a new level of precision and efficiency. These game-changing tools are designed to deliver clean, consistent welds, ensuring superior quality in various applications. From intricate metal fabrication to crucial hail damage repair, the advanced technology incorporated into modern welding equipment is transforming the industry.

With features like computer-aided control systems, automated arc stabilization, and precise temperature regulation, these machines enable technicians to achieve remarkable results. This not only speeds up the process but also minimizes errors, making it an invaluable asset in demanding sectors such as automotive repair. The ability to create consistent welds with reduced heat input and minimal spatter means that advanced welding equipment is a key player in maintaining structural integrity while reducing waste.

Clean Welds: The Key Benefits Unveiled

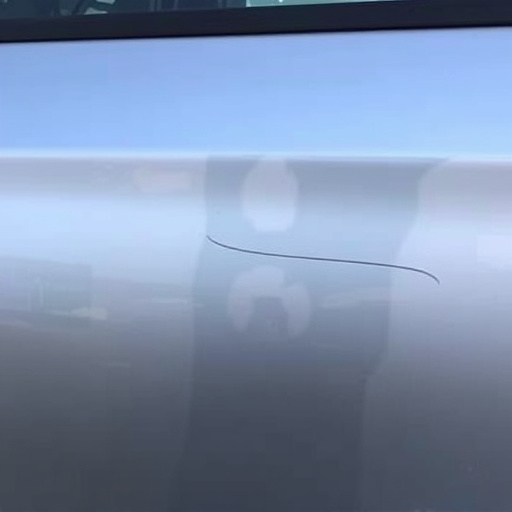

Clean welds are not just aesthetically pleasing; they are a testament to the precision and efficiency of advanced welding equipment. In industries like automotive repair, specifically collision repair and dent removal, maintaining consistency in weld quality is paramount. Advanced welding equipment supports clean welds by offering precise control over parameters such as heat input, arc length, and gas flow. This ensures that each weld meets strict standards for strength and integrity, eliminating defects that can compromise the structural soundness of vehicles during auto maintenance processes.

Moreover, these innovative tools minimize spatter and smoke, creating a cleaner work environment. The reduced need for post-weld cleaning not only saves time but also minimizes the risk of contamination or damage to surrounding materials. By delivering consistent, high-quality welds, advanced welding equipment streamlines collision repair processes, enhances overall productivity, and contributes to safer, more reliable end products.

Consistent Results: How Tech Enhances Quality

Advanced welding equipment plays a pivotal role in ensuring consistent results during the welding process. Modern technology has revolutionized the way welders carry out their tasks, leading to higher-quality outcomes. These cutting-edge tools offer precise control over various parameters, such as heat input and arc stability, which are crucial for achieving clean and consistent welds.

In the realm of car body repair, including complex jobs like Mercedes Benz collision repair or intricate car body restoration, advanced welding equipment is indispensable. By automating and optimizing key processes, these tools minimize errors and variations, resulting in stronger, more aesthetically pleasing welds. This, in turn, enhances the overall quality and durability of the repaired vehicles, satisfying both technicians and customers alike.

Advanced welding equipment, with its innovative features and precise control, is transforming the welding process. By prioritizing clean welds, these tools not only enhance structural integrity but also ensure consistent quality across projects. Investing in advanced welding equipment proves to be a game-changer for industries seeking efficient, high-quality results, ultimately revolutionizing their workflow.