In today's competitive automotive market, advanced welding equipment is revolutionizing structural repairs in auto body shops. Technologies like laser welding and robot-assisted systems offer unprecedented precision and efficiency, reducing errors, improving tolerances, and strengthening structural integrity. These innovations cater to various repair tasks, from minor damage to complex metal fabrication, ensuring high-quality outcomes while saving time and resources. Case studies demonstrate significant improvements in repair quality across industries, with advanced equipment providing stronger, more durable repairs compared to traditional methods.

Advanced welding equipment is transforming structural repair quality, offering precision and efficiency previously unattainable. This article explores how modern technology, featuring automated systems, laser guidance, and advanced materials, revolutionizes repairs across various industries. We delve into key benefits, present compelling case studies, and highlight the growing importance of adopting these innovations for superior, cost-effective, and durable structural restoration. Discover how advanced welding equipment is setting new standards in repair quality.

- Understanding the Impact of Advanced Welding Equipment

- Key Features of Modern Welding Technology for Structural Repairs

- Case Studies: Demonstrating Improved Repair Quality with Advanced Tools

Understanding the Impact of Advanced Welding Equipment

In today’s competitive market for automotive services, understanding the impact of advanced welding equipment is crucial. These innovative tools are transforming the landscape of structural repair in auto body shops and beyond. By employing cutting-edge technology, such as laser welding and robotically assisted systems, technicians can achieve unparalleled precision and efficiency. This not only speeds up the repair process but also enhances the overall quality of work.

The integration of advanced welding equipment brings multiple benefits to both automotive body shops and their customers. It reduces the risk of errors, ensures tighter tolerances, and improves the structural integrity of repairs. Moreover, it facilitates a smoother transition from initial damage assessment to final auto painting stages, guaranteeing a seamless finish. In essence, embracing these technologies is not just a step forward; it’s a leap towards revolutionizing the way we perceive and deliver automotive body repair services.

Key Features of Modern Welding Technology for Structural Repairs

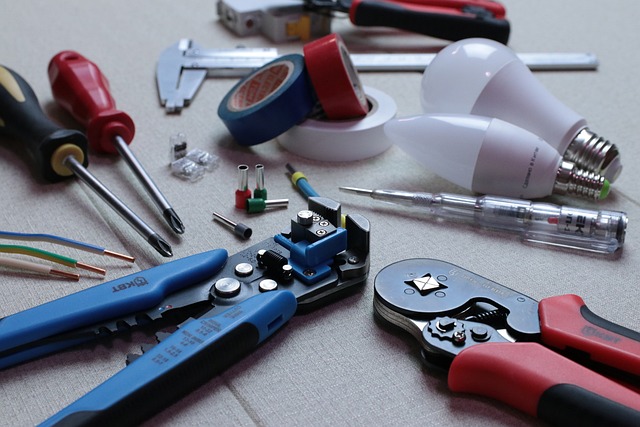

Modern welding technology for structural repairs boasts several key features that set it apart from traditional methods. One of the most notable advancements is the integration of advanced welding equipment, designed to enhance precision and efficiency. These machines often incorporate automated processes, ensuring consistent weld quality across various materials and configurations. For instance, robotic welding systems can precisely position and manipulate welding torches, leading to minimal error rates and reduced human fatigue during lengthy repairs.

Furthermore, contemporary welding technology offers improved control over heat input, a critical factor in structural repair. Specialized equipment enables welders to tailor the heating and cooling processes, resulting in stronger, more durable bonds. This is particularly beneficial in scenarios such as fender repair or car scratch repair, where maintaining structural integrity while mitigating damage is paramount. The versatility of modern welding technology also accommodates diverse repair tasks, from minor car damage repairs to complex metal fabrication projects.

Case Studies: Demonstrating Improved Repair Quality with Advanced Tools

In recent years, case studies have shown that implementing advanced welding equipment significantly enhances the quality of structural repairs in various industries. These innovative tools offer precision and control unmatched by traditional methods, leading to stronger, more durable repairs. For instance, in the automotive sector, car bodywork services have benefited greatly from advanced welding technology. Modern techniques such as laser welding provide clean cuts and precise fusions, minimizing heat input and potential damage to surrounding materials. As a result, auto body restoration projects exhibit superior structural integrity, ensuring vehicles’ safety and performance for extended periods.

Furthermore, advanced equipment has streamlined the repair process, saving time and resources without compromising quality. In car paint repair, automated welding robots can efficiently apply consistent pressure and heat, facilitating faster drying times and reducing paint defects. This not only speeds up the overall restoration process but also improves the final aesthetic appeal of the vehicle’s exterior. These case studies highlight how advanced welding equipment is transforming traditional repair services into more efficient, precise, and high-quality operations.

Advanced welding equipment plays a pivotal role in enhancing structural repair quality, offering precision and efficiency unmatched by traditional methods. By leveraging key features like automated control, enhanced visibility, and improved heat management, modern welding technology ensures stronger, more durable repairs. Case studies highlight successful transformations, demonstrating the significant impact of these advanced tools on safety, speed, and overall project outcomes. Adopting this innovative equipment is not just a trend; it’s a strategic move towards superior structural integrity in various industries.