Advanced welding equipment is revolutionizing vehicle manufacturing and repair by providing stronger welds, streamlined body repairs, reduced weight, enhanced aesthetics, and improved safety features. It enables precise, efficient, and environmentally-friendly production processes, benefiting businesses aiming for competitive edge in the market while ensuring top-tier customer satisfaction.

Modern vehicles demand superior craftsmanship, and advanced welding equipment plays a pivotal role in meeting these demands. This technology enhances vehicle durability and safety by creating robust bonds that withstand rigorous testing. On assembly lines, efficient welding streamlines production, reducing costs and improving efficiency. Moreover, advanced techniques unlock innovative design possibilities, allowing for lighter, more complex structures. Investing in cutting-edge welding equipment is not just a trend; it’s a necessity for the future of automotive manufacturing.

- Enhancing Vehicle Durability and Safety through Advanced Welding

- Streamlining Production: Efficient Welding for Modern Assembly Lines

- Unlocking Design Possibilities: The Role of Advanced Welding Techniques

Enhancing Vehicle Durability and Safety through Advanced Welding

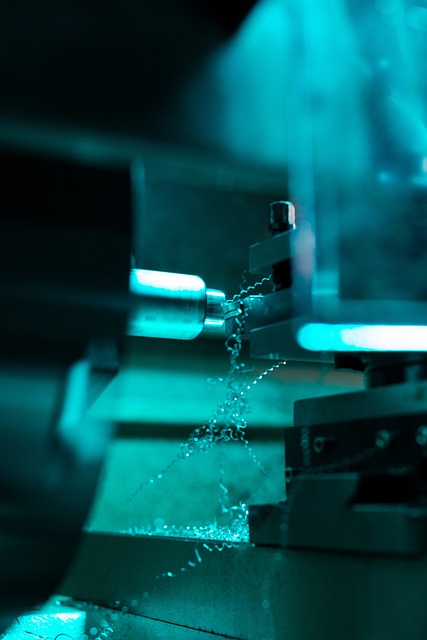

Advanced welding equipment plays a pivotal role in enhancing the durability and safety of modern vehicles. The intricate designs and complex materials used in contemporary car manufacturing demand precise and robust joining techniques, which advanced welding machinery provides. These innovative tools enable more consistent and stronger welds, ensuring that every component is securely integrated into the vehicle’s structure. This not only improves overall structural integrity but also boosts safety standards, especially in critical areas like chassis and body panels.

By employing advanced welding equipment, vehicle body repair and restoration processes are significantly streamlined. It facilitates intricate dent repairs and precise reshaping of metal surfaces, restoring vehicles to their pre-accident conditions. This level of precision is crucial for maintaining the aesthetic appeal and safety features that modern vehicles boast. Moreover, advanced welding techniques contribute to lighter vehicle weights, thereby improving fuel efficiency and reducing environmental impact, making it a key aspect of sustainable automotive practices.

Streamlining Production: Efficient Welding for Modern Assembly Lines

In modern vehicle manufacturing, advanced welding equipment plays a pivotal role in streamlining production processes across assembly lines. This technology enables precise, efficient, and consistent welds, ensuring structural integrity and quality control. With its ability to handle intricate designs and diverse material types, advanced welding equipment contributes significantly to reducing manufacturing time without compromising safety standards.

For collision repair centers and auto body shops, investing in this modern equipment is crucial. It facilitates faster repairs, enhances the precision of vehicle dent repair, and ultimately improves customer satisfaction by delivering top-notch finishes. By embracing these advancements, businesses can stay competitive in an industry where efficiency and quality are paramount, whether it’s for regular maintenance or complex accident repairs.

Unlocking Design Possibilities: The Role of Advanced Welding Techniques

In the realm of modern vehicle manufacturing and customization, advanced welding equipment has emerged as a game-changer. The traditional methods, while effective for basic structures, often restrict designers from pushing boundaries. Advanced welding techniques, however, unlock a new world of possibilities. These innovative processes allow for intricate, seamless welds, enabling automotive designers to create complex shapes and structures previously impossible.

The use of advanced welding equipment facilitates the crafting of vehicles with dynamic curves, lightweight frames, and precise joints. This not only enhances aesthetic appeal but also improves overall vehicle performance. In terms of auto painting and vehicle repair, these techniques ensure a smoother surface finish, promoting better paint adhesion and reducing the need for extensive vehicle paint repair. Thus, advanced welding equipment plays a pivotal role in both the design and structural integrity of modern vehicles.

Advanced welding equipment is no longer a luxury but an indispensable tool for modern vehicle manufacturing. As vehicles become more complex and lightweight, efficient welding techniques are essential for enhancing durability, safety, and design flexibility. By streamlining production processes and enabling innovative construction methods, advanced welding equipment plays a pivotal role in keeping modern vehicles at the forefront of technology and performance. Investing in these technologies is crucial for automakers to remain competitive in today’s market.