Advanced welding equipment revolutionizes metalwork with digital controls, automation, and diverse material handling. These features ensure higher precision, faster completion times, and intricate task capabilities, making them ideal for car bodywork, artistic welds, and industrial applications like auto repair. By streamlining processes, reducing human error, and providing consistent results, advanced welding systems are a game-changer across various sectors.

In today’s industrial landscape, efficient and precise welding is paramount. While basic welding tools have long been the go-to for many, understanding the distinct advantages of advanced welding equipment can revolutionize operations. This article delves into the world of cutting-edge welders, highlighting how their key features elevate efficiency and craftsmanship. From smart technology to enhanced control, advanced welding equipment promises faster turnaround times, improved accuracy, and superior results—a true game changer for professionals.

- Understanding Basic Welding Tools and Their Limitations

- Key Features of Advanced Welding Equipment

- Improved Efficiency: The Power of Advanced Technology

Understanding Basic Welding Tools and Their Limitations

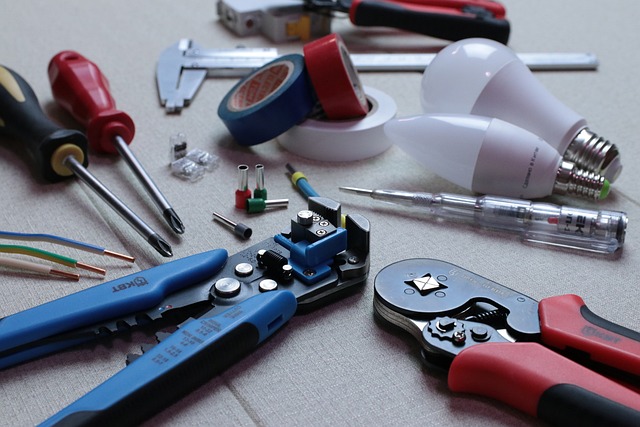

Welding is a fundamental process in various industries, from construction to automotive sectors, and understanding its tools is crucial. Basic welding equipment includes torches, guns, and sticks designed for general-purpose welding tasks. These tools are accessible, affordable, and suitable for beginners or minor repairs like fixing a broken fence or small metal projects. However, they have limitations when it comes to precision and versatility. For instance, standard welding equipment may struggle with intricate designs, complex geometries, or demanding applications like car dent removal and bumper repair, where advanced techniques and specialized tools are required.

Advanced welding equipment represents a significant leap from basic tools, offering improved performance and capabilities. These include features such as digital controls for precision, automated functions to enhance efficiency, and versatile designs suitable for diverse materials and projects, from metal fabrication in car bodywork services to intricate artistic welds. They cater to professionals and enthusiasts seeking higher quality outcomes, faster completion times, and the ability to tackle complex tasks with ease.

Key Features of Advanced Welding Equipment

Advanced welding equipment distinguishes itself from basic tools through a confluence of innovative features designed to enhance precision, efficiency, and safety. These machines often incorporate digital controls, offering precise adjustments for temperature, speed, and current flow, ensuring consistent and high-quality welds across various materials. Automated or semi-automated functions further streamline the process, significantly reducing the risk of human error and allowing for faster production times, ideal for industrial applications like auto body repair, where quick bumper repairs and dent removals are common tasks.

Moreover, advanced equipment often features robust construction and durable components, built to withstand strenuous use in demanding environments. Integrated safety mechanisms, such as overload protection, automatic shutdowns, and ergonomic designs, prioritize the welder’s comfort and well-being. These machines also support a broader range of welding techniques and materials, from steel and aluminum to exotic alloys, making them versatile tools for specialized projects that basic equipment may struggle to handle.

Improved Efficiency: The Power of Advanced Technology

Advanced welding equipment is a far cry from the basic tools used in traditional welding practices. The integration of modern technology has revolutionized the welding process, making it faster, more precise, and overall more efficient. These advanced systems are designed to streamline various aspects of welding, from material handling to heat management and energy distribution. As a result, welders can achieve higher quality outcomes in less time.

For example, automated welding robots equipped with sensors and AI capabilities can precisely execute complex welding patterns, minimizing human error. Moreover, advanced equipment often incorporates real-time data analytics, allowing for immediate adjustments and ensuring consistent results. This level of precision is particularly beneficial in industries like automotive and fleet repair services, where maintaining high standards is crucial. Even tasks that once required manual labor or multiple steps can be simplified and optimized with the right advanced welding equipment, making it an invaluable asset for any professional, whether they specialize in auto repair near me or industrial applications.

Advanced welding equipment stands out from basic tools with its innovative features, offering improved efficiency and precision. By embracing these cutting-edge technologies, professionals can elevate their welding capabilities, making complex tasks simpler and faster. Investing in advanced welding equipment is a game-changer for those seeking to enhance their skills and stay ahead in the industry.